In steel pipe welding operations, weld blackening is a common problem plaguing many enterprises. Blackened welds not only affect the appearance of products and reduce the high-end texture of finished products, but may also imply potential welding quality hazards. The core cause of this problem is the oxidation of the weld surface or the high-temperature oxidation of surrounding materials. Multiple factors such as workpiece pretreatment, protective gas purity, welding process parameters, tungsten electrode selection and spacing, and welding material compatibility will directly aggravate the oxidation blackening phenomenon.

I. Analysis of Core Causes of Weld Blackening

Inadequate workpiece pretreatment: Failure to thoroughly remove stains and impurities on the workpiece surface before welding directly affects the bonding degree of the welding interface and easily causes oxidation blackening;

Substandard argon protection: Insufficient argon purity, improper flow regulation, or too late gas supply and too early gas stop lead to the loss of effective protection of the weld seam and cause oxidation;

Improper selection and use of tungsten electrodes: Poor quality of tungsten electrodes or blunting after long-term use will result in scattered current, which is likely to cause local high-temperature oxidation during welding;

Unbalanced control of welding spacing: Either too close or too far distance between the tungsten electrode and the workpiece will damage the arc stability and increase the probability of blackening;

Unreasonable welding process parameters: Excessively large welding current and too slow welding speed will lead to prolonged high-temperature residence time and excessive heat input; deviations in the welding torch angle will affect the stability of protective gas delivery, all of which will cause weld blackening;

Poor compatibility of welding materials: There are many types of stainless steel and other materials with complex compositions. Different materials have great differences in temperature resistance and welding process requirements. Uneven materials are prone to oxidation blackening.

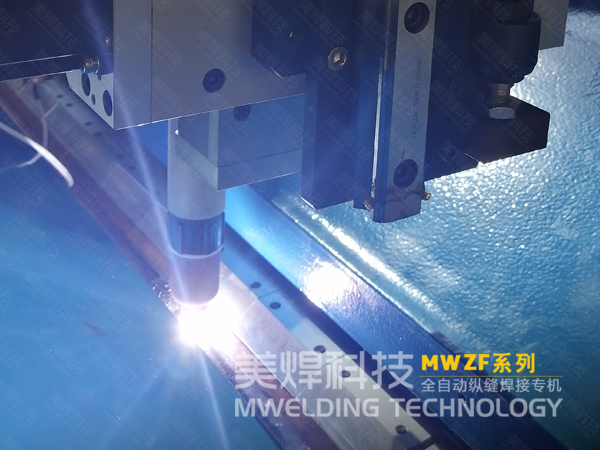

II. MWELDING MWF Series Enclosed Pipe-to-Pipe Welder: Targeted Solution

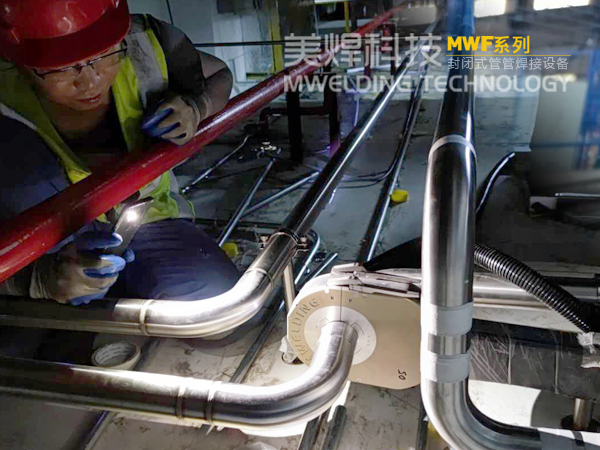

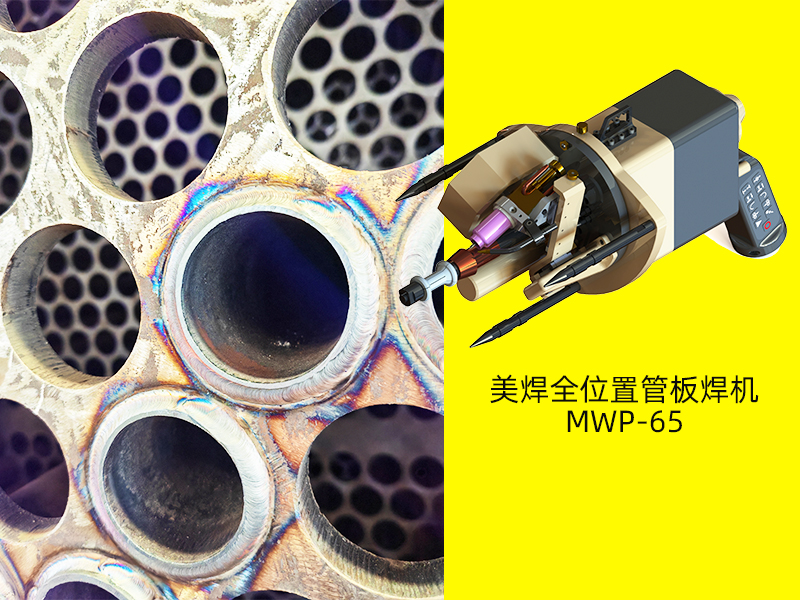

Faced with the pain point of weld blackening, the MWF Series Enclosed Pipe-to-Pipe Welder launched by Shanghai MWelding Intelligent Technology Co., Ltd. has become the preferred equipment to solve the problem with its precise design and core technology. This series of welders is specially designed for thin-walled stainless steel pipe welding, adopting imported core components, with the advantages of safety, precision, durability and reliability. It is widely applicable to the all-position welding of various pipes with a diameter of 3.17-219mm, and can realize autogenous welding such as butt joint and insertion of stainless steel, carbon steel and titanium alloy steel pipes, achieving single-sided welding and double-sided forming, with smooth inner and outer walls without secondary grinding. The welding torch is light in weight, and the expert welding parameters can be operated with one key, which is easy to learn and does not generate heat during long-time work.

Core Technical Advantages to Inhibit Blackening from the Source

Four-channel argon protection + precise gas control: The equipment is equipped with a 4-channel argon protection system inside, combined with an adaptive high-purity argon supply scheme, ensuring that the weld seam and heat-affected zone are under effective protection throughout the process, blocking oxidation reactions from the source and making the weld seam cleaner and more beautiful;

Intelligent process parameter control: Equipped with an expert database for pipe-to-pipe automatic welding, it can accurately match welding current, voltage, speed and other parameters according to different welding materials, avoiding high-temperature oxidation caused by unbalanced parameters; the speed measurement feedback function makes the welding torch rotation speed (0.2-4rpm) accurate and stable, and combined with the circulating water cooling design, it effectively controls the heat input and prevents overheating during long-time welding;

High-quality accessories and reasonable structural design: Adapt to 1.6/2.4mm high-quality tungsten electrodes to ensure concentrated and stable current; the full water cooling design of the welding torch head not only extends the service life of the welding torch, but also avoids equipment heating affecting welding stability, further reducing the hidden danger of blackening;

Integrated supporting and precise positioning: It can be used with the MWA-200 integrated control power supply to realize all-position TIG pipe-to-pipe automatic welding, solving the problem of unstable process in traditional manual pipe-to-pipe welding; it is equipped with a flexible fixture system, with precise positioning and reliable welding, avoiding protection failure caused by workpiece displacement.

Multiple Core Values, Balancing Efficiency and Cost

Improvement of both quality and efficiency: It completely solves the pain points of unstable process and high rework rate of traditional manual welding, with good welding forming and stable output, saving at least 30% of labor costs, and greatly improving welding efficiency and finished product qualification rate;

Easy to operate and learn: The preset expert parameters allow operators to quickly master operating skills, achieve the best welding effect without complex training, and reduce the technical threshold;

Customization and full-process service: As a professional manufacturer of pipe-to-pipe welding equipment, MWELDING supports personalized customization services, can create exclusive pipe welding equipment according to the needs of different fields, and provides full-process technical support to realize a turnkey and assured service.

Detailed Technical Parameters

III. Choose MWELDING to Unlock a High-end Welding Experience

Adhering to the business philosophy of "customer-oriented, customized according to needs, and integrated service without outsourcing", Shanghai MWELDING focuses on the R&D and production of automatic pipe-to-pipe welding equipment, automatic tube-sheet welding equipment and integrated welding control power supply, and strives to build a high-end brand of professional pipe welding equipment.

Whether it is solving quality problems such as weld blackening, or improving welding efficiency and reducing production costs, the MWELDING MWF Series Enclosed Pipe-to-Pipe Welder can provide high-quality solutions. For more information about automatic pipe-to-pipe welding machines, tube-sheet welding equipment and related services, please call 18918961606 or visit the official website of Shanghai MWELDING at https://www.mwelding.com.cn for consultation. MWELDING looks forward to your trust and will wholeheartedly provide you with high-value-added products and technical services!